Choosing the perfect photochemical reactors for your Photochemistry Analysis

What are the most important factors?

The thing that sits right at the top of our list is repeatability. There are still scientists out there using homemade photoreactor kit in their labs (which is scary and potentially hazardous) with a lamp and some clamps to carry out their reactions. Detailing this set up precisely in your documentation can be tricky and changing any detail (even something seemingly insignificant such as using a new LED) can completely change that reaction, rendering it far more difficult to repeat.

The next factors to consider are the intensity of the light reaching the sample, the wavelengths emitted, and the temperature in the vial/flask which are all key to a positive result.

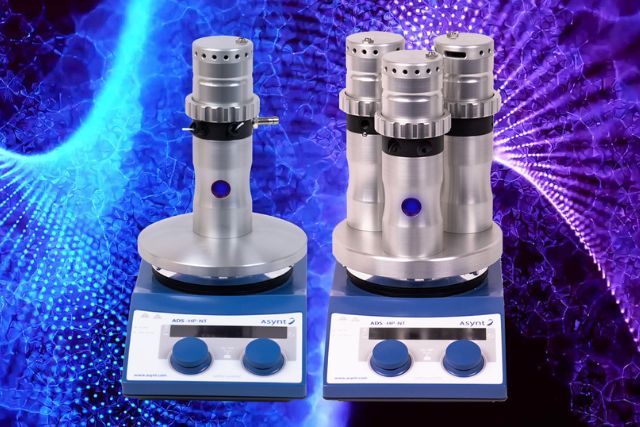

Commercially produced photoreactors give users optimum uniformity and repeatability of their reactions but, depending on which brand or model reactor you use, there’s going to be variety between research groups from using different equipment, using different methods to control the temperature of their reaction, and using different sized vials/flasks which effect how the light source reaches the sample.

So how do I choose the perfect photochemical reactor for my work?

Wavelength: Different types of LED can vary dramatically in wavelength and intensity. By ensuring that you use the same type, and the right wavelength for your reaction, you can optimise your process. Using a reactor with built-in flexibility to accommodate multiple wavelengths enables greater use of the system, as more reactions can be carried out, therefore also achieving better value for money.

Temperature: The very nature of a photochemical reactor means that over the course of the reaction the temperature will naturally increase as a side effect of the light. If a precise temperature is key, scientists must be able to control it. External cooling fans or circulator systems bring another variable into the picture so a system with temperature control is highly desirable. Read More…