Knowing Which Ender 3D Printer Suits My Industrial Needs Best

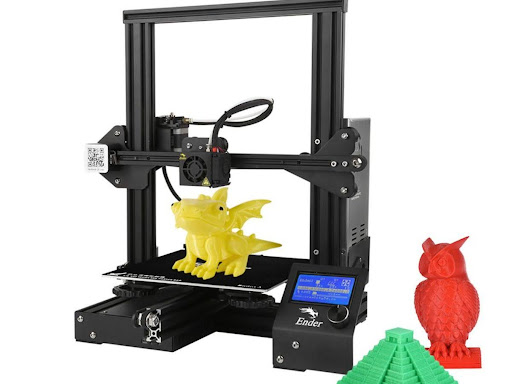

Among the most recognized names in this space is the Ender 3D printer series—manufactured by Creality—which offers a range of FDM printer models suitable for both personal and professional use.

The use of 3D printing in industrial and prototyping environments has grown rapidly over the past decade. Among the most recognized names in this space is the Ender 3D printer series—manufactured by Creality—which offers a range of FDM printer models suitable for both personal and professional use. For businesses looking to integrate 3D printing into their operations, the key lies in selecting the right model that aligns with specific industrial needs.

Whether it’s producing functional prototypes, low-volume end-use parts, or custom jigs and fixtures, understanding the capabilities and differences within the Ender series can help optimize your workflow and output.

Understanding FDM Technology in Industrial Contexts

The FDM printer (Fused Deposition Modeling) is the most widely adopted 3D printing technology in industrial settings due to its reliability, material range, and ease of use. It works by extruding thermoplastic filament layer by layer to form solid objects. The Ender lineup operates using this method and supports a wide range of filament types including PLA, ABS, TPU, PETG, and more.

FDM printers like those in the Ender range are especially valuable for:

- Rapid prototyping and iteration

- Producing custom or replacement machine parts

- Small-batch manufacturing

- Functional testing of components before mass production

This makes them a strong fit for sectors like manufacturing, engineering, education, automotive, and product design.

Overview of Ender 3D Printer Models

The Ender 3D printer series includes several models with variations in build size, features, and upgrade potential. While many are designed with hobbyists in mind, several newer or enhanced versions are more than capable of supporting light industrial and semi-professional applications.

1. Ender-3 V2

Build Volume: 220 x 220 x 250 mm

Use Case: Reliable for smaller prototypes, test pieces, and concept modeling

Key Features: Silent stepper drivers, glass bed, stable motion system

Best For: Offices, design studios, and education centers needing moderate-volume 3D printing

2. Ender-3 S1 and S1 Pro

Build Volume: 220 x 220 x 270 mm

Use Case: Ideal for flexible filament printing and applications requiring higher detail

Key Features: Direct drive extruder, auto bed leveling, higher temp compatibility

Best For: Industrial designers, R&D teams, and businesses needing better material versatility

3. Ender-5 S1

Build Volume: 220 x 220 x 280 mm

Use Case: Enhanced speed and precision for iterative design or light production

Key Features: Cubic frame for stability, rapid movement, compatibility with high-temp materials

Best For: Small manufacturers or repair departments needing fast part turnaround

4. Ender-3 Max Neo

Build Volume: 300 x 300 x 320 mm

Use Case: Larger part fabrication and higher-volume printing

Key Features: Carborundum glass bed, auto-leveling, silent board

Best For: Businesses that prioritize space for prototyping and use large 3D printers for single-piece applications.

Factors to Consider When Choosing for Industrial Use

Not every 3D printer in the Ender line will suit every task. Choosing the right one depends on a number of operational and environmental factors.

1. Part Size Requirements

Consider the dimensions of your most commonly printed objects. If projects routinely exceed 250 mm in any axis, a larger model like the Ender-3 Max Neo is more suitable.

2. Print Volume and Speed

In environments where time-to-part is critical, higher-speed printers with solid frame stability (like the Ender-5 S1) may help maintain production efficiency.

3. Material Compatibility

Different applications require different filament properties. For example:

- ABS and PETG for functional, temperature-resistant parts

- TPU for flexible, wear-resistant components

- PLA for fast, low-cost prototypes.

Ensure the model selected supports the desired materials in terms of both hotend and bed temperature.

4. Environmental Noise and Space Constraints

Office environments or labs may benefit from silent boards and enclosed frames to reduce noise levels and contain emissions. The Ender-3 V2 and S1 models excel in quieter operations.

5. Upgrade Potential

One of the strengths of the Ender series is their modular design, allowing for aftermarket upgrades such as:

- Enclosures for better material control

- Dual Z-axis kits for stability

- All-metal hotends for higher temperature printing

This is especially helpful for businesses looking to evolve their printing capabilities without full equipment replacement.

The Role of Support and Availability

For those sourcing 3D printers in Canada, accessibility to spare parts, customer service, and firmware updates is an important part of the investment. The popularity of the Ender line ensures a wide support community and a steady supply of components. It also means reduced downtime if maintenance or part replacement is needed.

Final Thoughts

The Ender 3D printer series offers a wide selection of models that can support everything from initial design validation to small-scale manufacturing. For businesses exploring FDM printer solutions, selecting a model that matches your production needs, material demands, and workflow scale is key.

Whether your application requires large 3D printers for full-scale prototypes or compact models for desktop use, the Ender lineup offers scalable, cost-effective options that integrate well into industrial environments. As the demand for 3D printers in Canada continues to rise, understanding the capabilities of each model can help organizations make smarter, long-term decisions.