Maximizing Efficiency in High-Volume Packaging with Peripheral Equipment

In today’s fast-paced manufacturing and packaging industries, operational efficiency is not just a competitive advantage—it’s a necessity. Businesses handling high-volume packaging must navigate tight deadlines, ensure quality control, and manage costs, all while keeping up with customer demand. This is where peripheral equipment plays a vital role. Designed to complement primary packaging machinery, peripheral equipment enhances workflow, minimizes downtime, and ensures seamless integration of processes, making it indispensable for high-volume operations.

Understanding Peripheral Equipment in Packaging

Peripheral equipment refers to auxiliary devices that support or augment the capabilities of core packaging machinery. These components are typically used to handle tasks like feeding, conveying, labeling, sealing, or quality inspection. While primary packaging machines handle the bulk of the work—such as filling containers or sealing products—peripheral equipment ensures that each step in the packaging line runs smoothly and efficiently.

For businesses managing large-scale packaging operations, integrating peripheral equipment means optimizing each phase of the process, reducing manual intervention, and enhancing overall throughput. The result? Faster turnaround times, consistent output, and significant cost savings.

Key Ways Peripheral Equipment Enhances Efficiency

1. Streamlining Workflow Automation

Automation is the backbone of modern packaging lines, especially for high-volume operations. Peripheral equipment, such as conveyors, feeders, and diverters, ensures the smooth movement of products between machines. For example, products exiting an automatic shrink wrap machine can be seamlessly transferred to a labeling station or quality inspection area without manual handling. This streamlined workflow minimizes bottlenecks and reduces the risk of errors caused by human intervention.

2. Improving Product Handling and Consistency

Peripheral equipment ensures consistent product handling, a crucial factor for high-volume packaging where uniformity is essential. Devices like robotic arms, automated feeders, and tray loaders can handle delicate or oddly shaped products with precision, ensuring they are positioned correctly for packaging. This precision reduces waste caused by misaligned products and enhances the overall quality of the packaged goods.

3. Enhancing Quality Control

High-volume operations must maintain strict quality standards to avoid costly recalls or customer dissatisfaction. Peripheral equipment, such as vision inspection systems, checkweighers, and metal detectors, helps ensure that every package meets required specifications. By identifying defects or inconsistencies early in the process, these tools prevent substandard products from reaching the market and reduce the need for rework.

4. Reducing Downtime

Unplanned downtime can be a significant obstacle in high-volume packaging. Peripheral equipment equipped with advanced monitoring systems can detect potential issues, such as jams or mechanical failures, before they escalate. This proactive approach minimizes interruptions and ensures the packaging line operates at peak efficiency. Additionally, quick-changeover features in peripheral equipment make it easier to switch between product lines, further reducing downtime.

5. Boosting Scalability

As businesses grow and demand increases, their packaging lines must be scalable. Peripheral equipment allows companies to expand their operations without a complete overhaul of existing machinery. For instance, adding new conveyors, sortation systems, or palletizers can help accommodate higher volumes, ensuring the packaging process keeps pace with production.

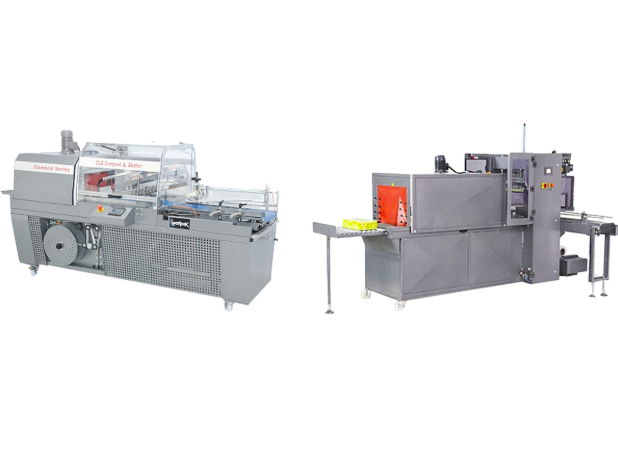

The Role of Automatic Shrink Wrap Machines in High-Volume Packaging

Shrink wrapping is a widely used method in high-volume packaging for its versatility, cost-effectiveness, and ability to protect products during transit. An automatic shrink wrap machine is a key component in this process, offering speed and consistency that manual or semi-automatic methods cannot match. However, to truly maximize the efficiency of these machines, peripheral equipment is essential.

For example, integrating conveyors to feed products into the shrink wrap machine ensures a continuous flow, eliminating delays. After wrapping, cooling tunnels or accumulation tables can streamline the transition to the next phase of packaging. This synergy between the automatic shrink wrap machine and peripheral equipment creates a fully automated system capable of handling large volumes with minimal oversight.

Conclusion: The Competitive Edge of Peripheral Equipment

In the competitive world of high-volume packaging, efficiency is the name of the game. Peripheral equipment serves as the unsung hero, working behind the scenes to optimize workflow, reduce waste, and ensure consistent quality. From conveyors and feeders to quality control devices, these auxiliary tools enable businesses to scale operations, meet tight deadlines, and deliver exceptional results.