Green hydrogen sounds like a win for developing countries. But cost and transport are problems

What is hydrogen used for?

Global hydrogen demand reached 94 million tons in 2021, and contained energy equal to about 2.5% of global final energy consumption. Only about 0.1% of current global hydrogen production is green, but big expansions are planned.

New applications for green hydrogen are also envisaged.

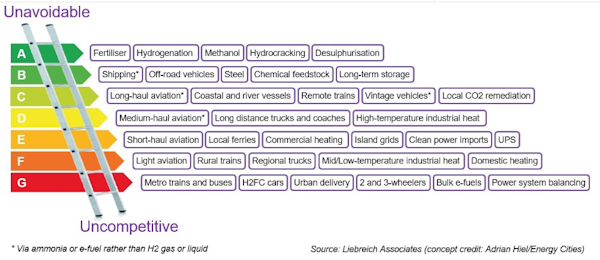

Liebreich’s classification is a useful indicator of the potential markets for green hydrogen.

Since the objective of using green hydrogen is really to reduce carbon dioxide, the applications to target first should be those that will yield the largest reductions in emissions. Liebreich’s ladder shows which they are. The applications in the (green) top row are an efficient use of valuable green hydrogen.

But green hydrogen currently costs much more to make than less clean types of hydrogen. Using it to produce the 180 million tons per annum of ammonia required globally for fertiliser production would have a severe knock-on effect on food prices.

So it is difficult to see how this transition is going to occur.

How is green hydrogen made?

Green hydrogen is made from water. Using renewable (“green”) electricity, equipment called electrolysers separates the hydrogen from oxygen in water (Hâ‚‚O). The process is called electrolysis.

Green hydrogen production emits no carbon dioxide, but the construction of renewable electricity infrastructure currently uses fossil fuels, which do emit carbon dioxide.

Hydrogen has traditionally been made from non-renewable energy sources like coal (“black hydrogen”) and natural gas (“grey hydrogen”). When these methods are combined with carbon capture and storage, the hydrogen produced is known as “blue hydrogen”. Read More…