Scratch-resistant metal oxide films made with simple printing technique

Researchers have developed a new, simple printing technique to create scratch-resistant metal oxide films, which could revolutionize various industries, including electronics, coatings, and optics. This breakthrough allows for the production of durable, high-performance films at a lower cost and with greater flexibility than traditional methods.

Metal oxide films are known for their hardness, chemical stability, and transparency, making them ideal for applications requiring protective coatings. However, producing these films typically involves complex, expensive processes such as sputtering or chemical vapor deposition, which require high temperatures and specialized equipment.

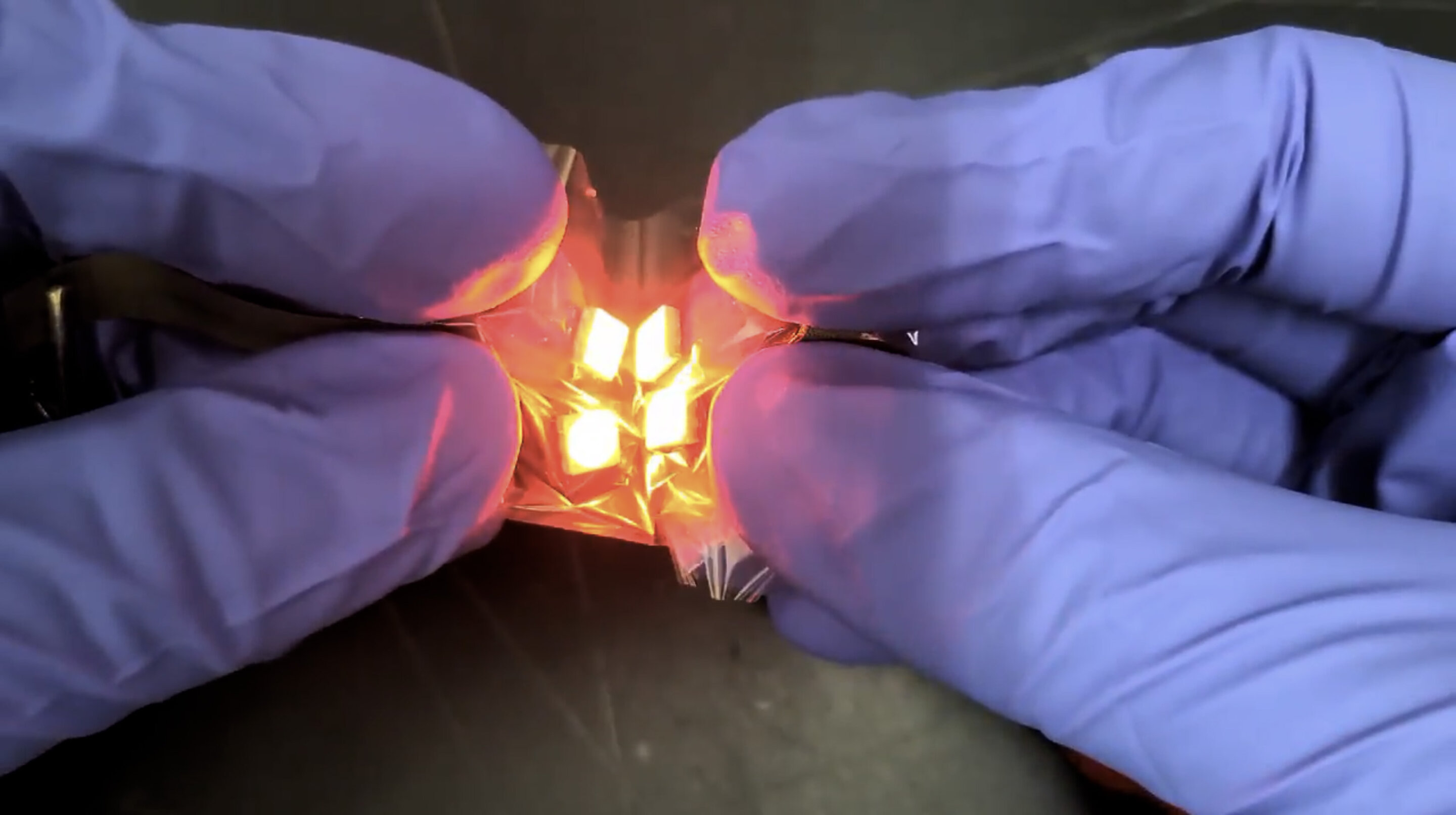

The new technique, developed by researchers, simplifies this process significantly. It involves a form of inkjet printing, where a liquid precursor solution containing metal ions is deposited onto a substrate. Upon heating, the solution undergoes a transformation, forming a thin, uniform metal oxide layer. This method is not only more cost-effective but also adaptable to different substrates, including plastics and flexible materials.

Key Advantages

- Scratch Resistance: The resulting metal oxide films exhibit excellent scratch resistance, making them ideal for use in protective coatings on devices like smartphones, tablets, and eyeglasses.

- Cost-Effective Production: The printing process is simpler and less expensive than traditional methods, reducing the overall cost of production. This could lead to more affordable consumer products and broader industrial applications.

- Versatility: The technique is versatile and can be applied to various substrates, including those that are flexible or sensitive to high temperatures. This opens up new possibilities for wearable technology, flexible displays, and other emerging technologies.

- Scalability: The process can be easily scaled up, making it suitable for mass production. This could accelerate the adoption of scratch-resistant coatings across different industries.

Applications

- Consumer Electronics: The most immediate application is in the consumer electronics industry, where the films can be used to create scratch-resistant screens for smartphones, tablets, and other devices.

- Automotive and Aerospace: In the automotive and aerospace industries, these films could be used to protect surfaces from wear and tear, enhancing the durability of components exposed to harsh conditions.

- Optics: The films' transparency and scratch resistance make them ideal for use in optical devices, such as lenses and displays.

- Industrial Coatings: The technique could be applied to create protective coatings for a wide range of industrial tools and machinery, reducing maintenance costs and extending the lifespan of equipment.

The development of this simple printing technique for scratch-resistant metal oxide films represents a significant advancement in materials science. As the technology matures, it could lead to more durable and cost-effective products across various sectors, from consumer electronics to industrial applications. The ability to produce these films on flexible substrates also paves the way for innovative uses in emerging technologies like flexible electronics and wearable devices.